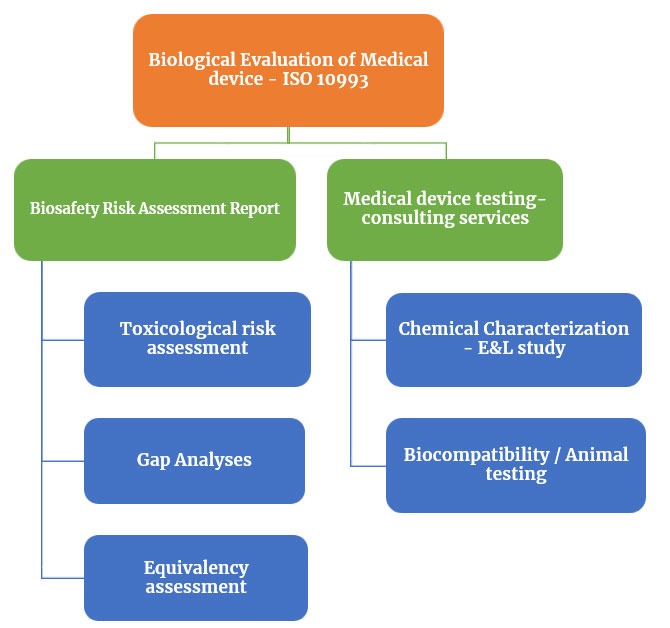

Medical device - Biological Evaluation [ISO 10993]

Biosafety Risk Assessment Report/ Medical Device Risk Assessment- ISO 10993-1

Professional Compilation of the whole set of information (Risk analysis, Risk evaluation, Risk control and Overall risk assessment) into a regulatory compliant risk assessment report to ensure the valuable product of the client is propelled into the market in a very short time.

Our experts concentrate on every phase of the product development like raw materials, processes, material testing, preclinical evaluation, biocompatibility studies, chemical characterization and even more to provide high-quality, meaningful biosafety risk assessment report compliant with ISO guidelines and regulatory requirements.

- Toxicological Risk Assessment: As part of Biological Evaluation Report, we evaluate the toxicity of individual chemical ingredients of the formulation used to manufacture a particular medical device. e.g. Tests for chemical composition, tests for extractable, leachable, and degradable materials

- Gap Analyses: Comprehensive analyses detailing acceptable and deficient areas (Gap) between an existing set of data and new regulatory requirements for devices, including reports of remediation and sequence recommendations.

- Equivalency Assessment: Evaluation of device equivalency to another similar marketed product; includes, properties and performance for clinical, technical and biological parameters, methods of use.

Medical Device Testing – Consulting Services

“Due to ever-changing International standards and guidelines, planning for biological safety and risk evaluation is as much a business necessity as it is a regulatory requirement. Consulting us at a preliminary level would Speed up product development & catapult the product into the market.”

ISO 10993 Page 31, section-B.3.2., mentions “Conducting animal testing for risk reduction should only be considered after all alternative courses of action (review of prior knowledge, chemical or physical characterization, in vitro evaluations or alternative means of mitigation) have been exhausted.”

Our collective expertise and wisdom will support you in above process.

Chemical characterisation / E & L studies: Characterize the implant material to understand the toxic effects of the material and for profiling & scanning all the possible impurities, and degradation to ensure product safety.

Biocompatibility /animal testing: Selective and minimal Biocompatibility/ safety testing may suffice to file application. Consult our risk evaluator to select test for you, this can save a huge testing cost and time.

WBR ensures quality work done at reputed partnering GLP/ NABL accredited lab.